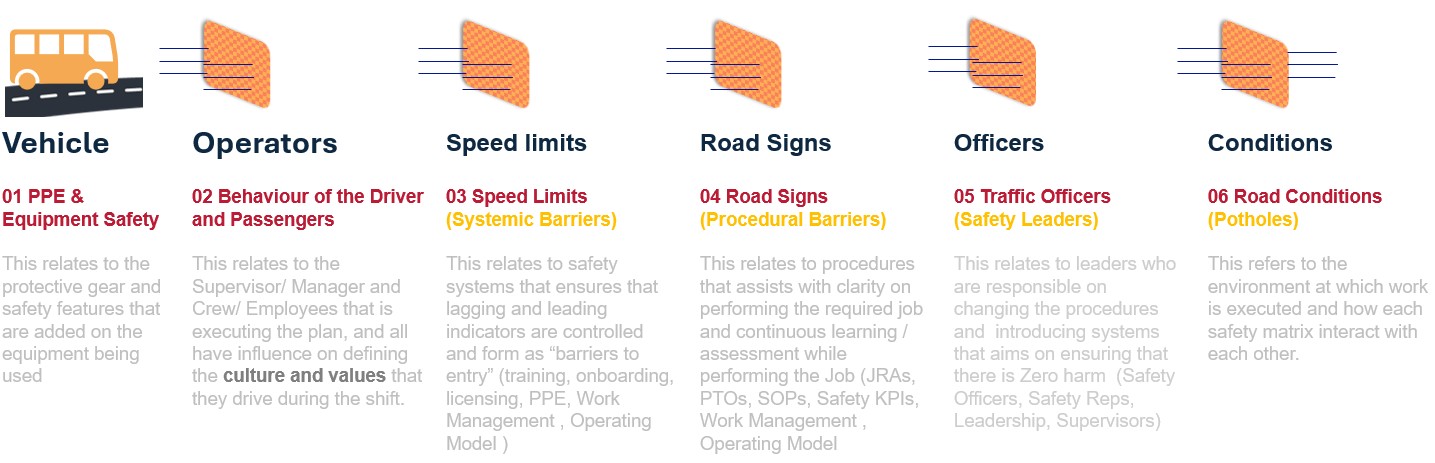

Safety is the main driver across all industries, but the more we treat it as a metric the higher probabilities of misunderstanding its basics. Most industries instead of treating the building blocks of safety they end up deploying additional controls which some might be highly exaggerated to be the cause of increased safety incidents. In industries like mining, simply increasing over inspection (plant walkabouts, visible field leadership, safety gemba, etc) does not address the complex interplay between human behavior, psychology, environment, equipment, and organizational culture that drives safety. Lets take the roadway safety and use this analogy to understand the importance of every aspects of safety and how organizations should start unlearning and learning the new way of building a safe culture which continuously innovate and improve the way of doing things.

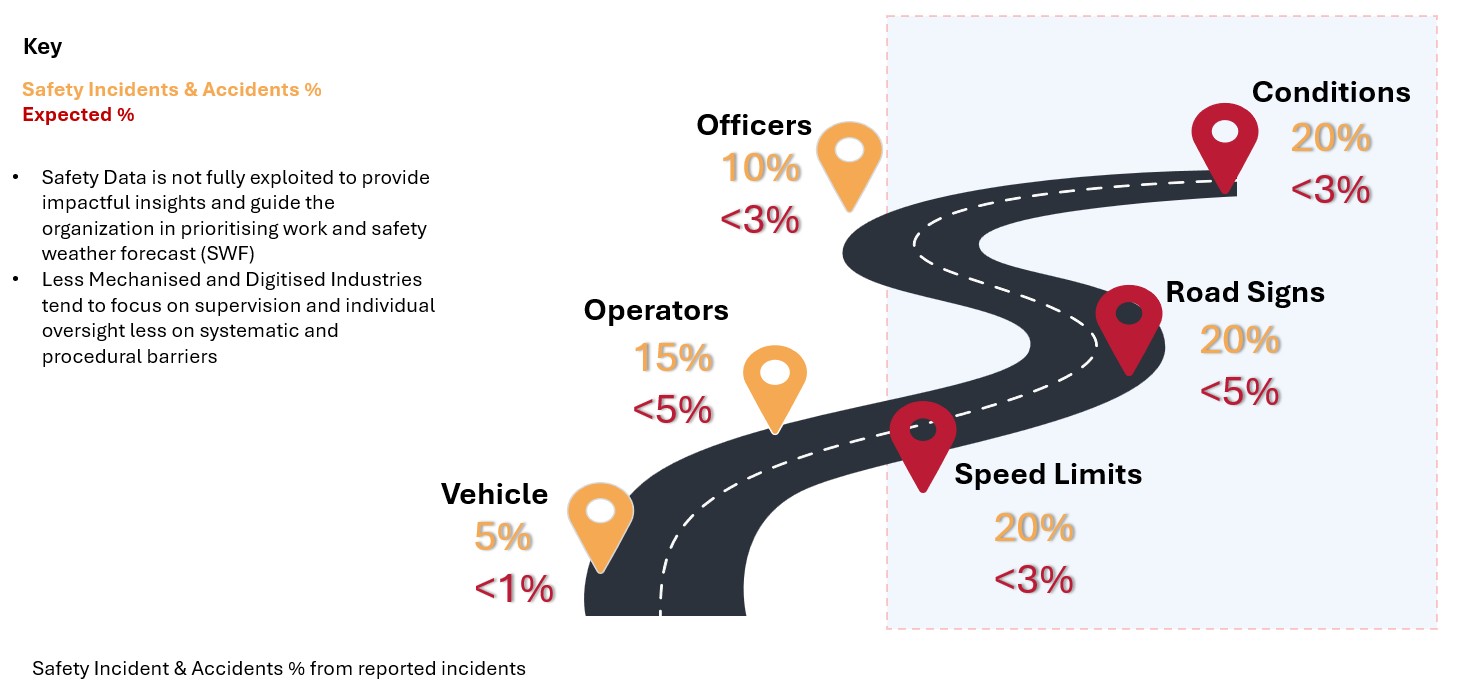

Organizations where mechanization and digitization are not aggressively implemented end up prioritizing supervision and individual oversight as the major driver of safety and do not fully utilize their data and inspections data to continuously improve critical controls in Safety. Below is the average percentage of incidents and accidents reported at mining and manufacturing industry indicating mostly that less mechanized and digitized industries focus on supervision and operator behaviour and neglect to prioritize the other critical controls.

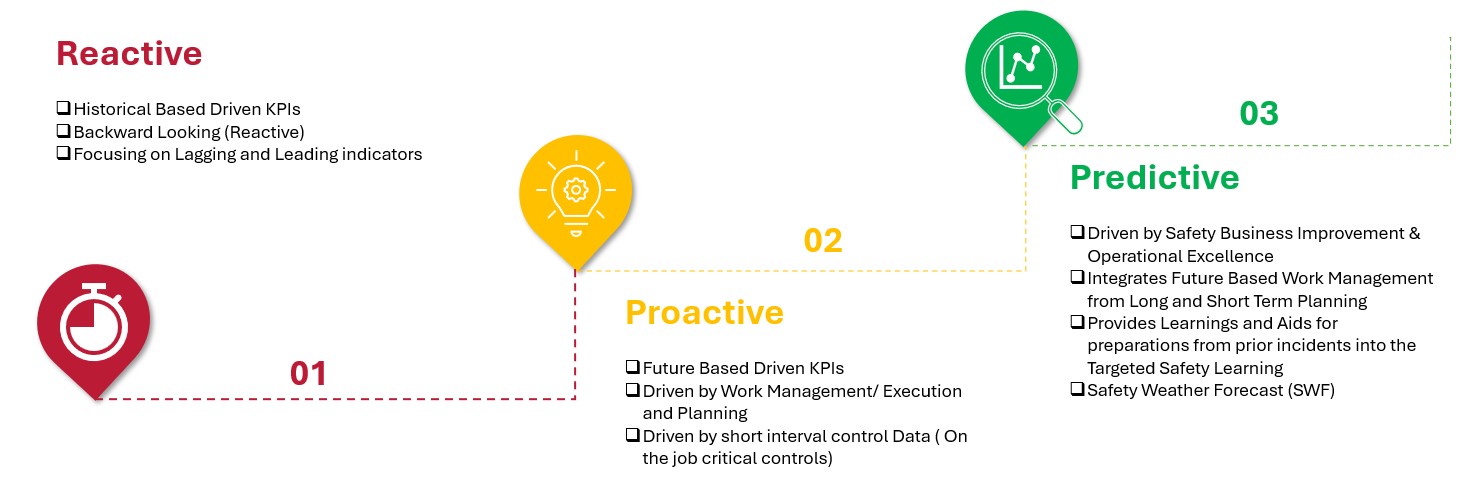

Safety as a KPI across most industries is a reactive based metric which mostly focus on historical incidents and future work requiring oversight (mostly high risk work). Minfutech is pioneering a paradigm shift in safety management, elevating it from a compliance-driven, administrative function to a strategic, consultancy-led approach. By integrating advanced technologies and predictive analytics, we enable organizations to transition from reactive, incident-driven safety management to proactive, data-informed decision-making. Our solution empowers leadership to adopt a forward-thinking safety strategy, leveraging insights and expertise to mitigate risks, optimize operations, and drive business excellence. This will allow operations to function on a predictive approach, which will help with future proofing daily work execution and working environment by providing targeted safety learnings and safety weather forecast (SWF). Through our unique blend of management and strategy consulting, we help clients unlock a culture of safety innovation, agility, and continuous improvement, ensuring a resilient and sustainable future.

MinFutech foresees a transformative future for industries, driven by the convergence of mechanization and digitization. As technology advances, industries will shift towards autonomous systems, AI, and IoT, unlocking new levels of efficiency, productivity, and innovation. Mechanization and digitization will create interconnected ecosystems, redefining work and industry. New business models, revenue streams, and value chains will emerge, driven by innovative services like robotics-as-a-service and AI-powered consulting. Augmented reality, virtual reality, and mixed reality will revolutionize training, design, and customer experience. MinFutech believes that this transformative future holds immense potential for economic growth, environmental sustainability, and societal progress. By prioritizing upskilling, reskilling, and education, we can ensure a prosperous future for all. In mining, autonomous technologies and advanced data analytics will optimize resource extraction and minimize environmental impact. Processing industries will leverage AI-driven insights and real-time monitoring to enhance efficiency and product quality. Manufacturing will evolve into smart factories, integrating robotics, IoT, and augmented reality to achieve unprecedented agility and productivity. Oil & Gas operations will adopt digital twins, AI-powered predictive analytics, and automation to optimize production, reduce emissions, and enhance safety.

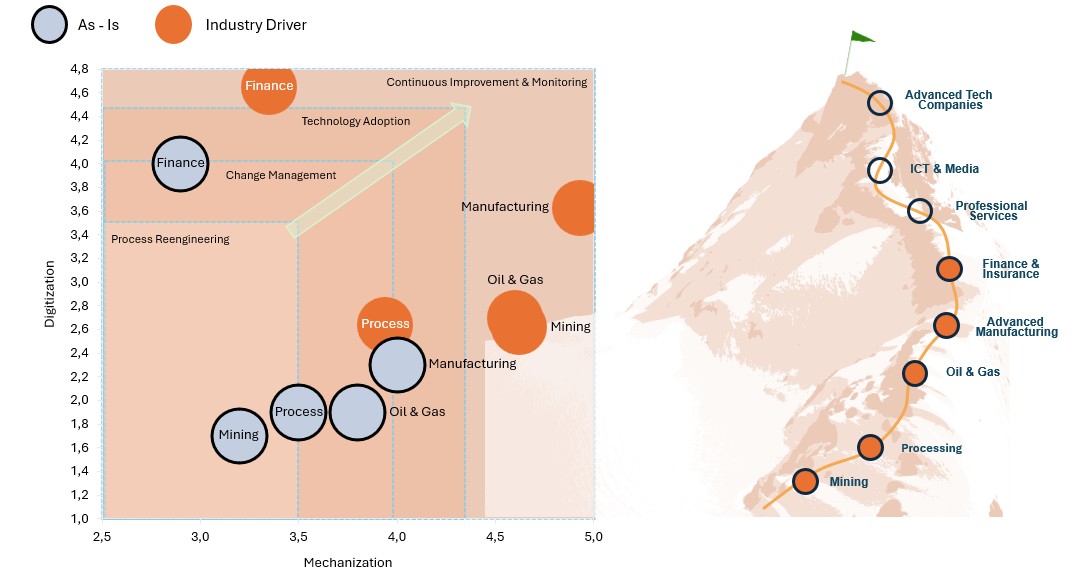

Our analysis reveals a distinct landscape of mechanization and digitization adoption across industries, underscoring the imperative for a strategic recalibration to unlock transformative growth. Mining and Oil & Gas sectors, while optimizing efficiency and scalability through mechanization, are lagging in digitization, with the exception of data-driven decision making, thereby missing a critical synergy opportunity. Conversely, Manufacturing and Finance are poised for disruptive innovation, having successfully harmonized digitization with their core business models, yielding enhanced agility and competitiveness. Meanwhile, Processing industries occupy a middle ground, necessitating a targeted intervention to bridge the mechanization-digitization divide and catalyze sustainable value creation. By articulating a cohesive strategy that converges mechanization and digitization, organizations can harness the transformative potential of these technologies, drive operational excellence, and capture new revenue streams in an increasingly complex and dynamic marketplace.

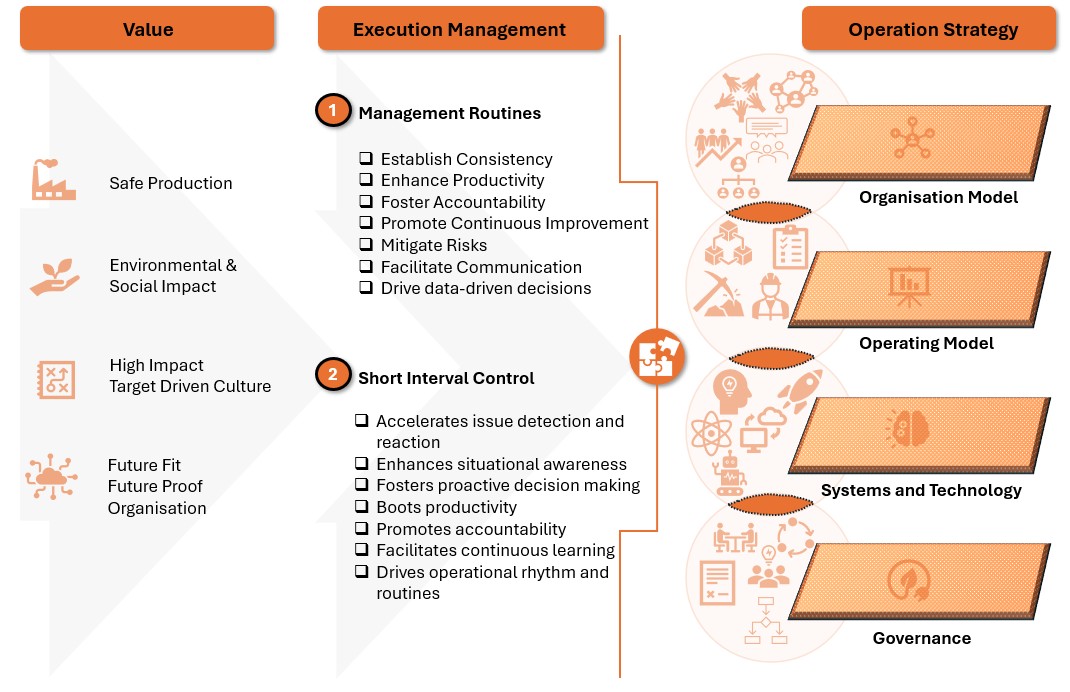

The operating and organisation model serves as the backbone of a company's culture, defining how work gets done, how decisions are made, and how values are upheld. A well-designed operating model fosters collaboration, innovation, and accountability, while a harmonious organization model promotes a shared sense of purpose, values, and behaviours. In the high-stakes industries of mining, manufacturing, processing, and oil and gas, a well-designed operating and organization model is the difference between success and stagnation. As companies strive to optimize production, reduce costs, and improve safety, their operating model must be aligned with their organizational culture to drive efficiency, innovation, and accountability. Meanwhile, the synergy between technologies and systems is crucial in supporting these models, enabling real-time monitoring, predictive maintenance, and data-driven decision-making. By harnessing the power of digitalization, automation, and advanced analytics, companies can unlock new levels of productivity, agility, and competitiveness. On MinFutech, we explore the latest trends, technologies, and strategies that are revolutionizing these industries, and provide insights on how to create a cohesive and dynamic ecosystem that sustains a vibrant culture and propels business success.

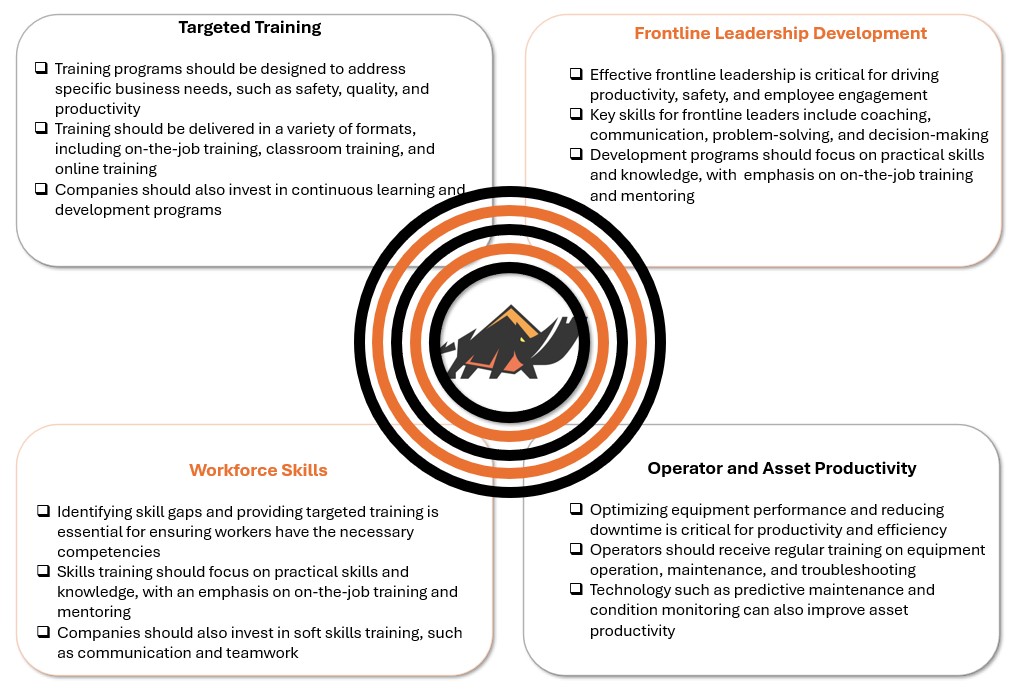

To truly transform workforce productivity, organizations must converge on four critical dimensions. Firstly, targeted training that bridges skill gaps and equips employees with future-proof capabilities. Secondly, frontline leadership development that empowers supervisors to coach, motivate, and inspire their teams. Thirdly, a relentless focus on workforce skills that fosters a culture of continuous learning, innovation, and knowledge-sharing. Lastly, operator and asset productivity that optimizes the intersection of human capability and technological efficiency, ensuring seamless workflows and minimized downtime. By harmonizing these elements, organizations can unlock a multiplier effect that amplifies productivity, drives operational excellence, and sustains long-term competitiveness.

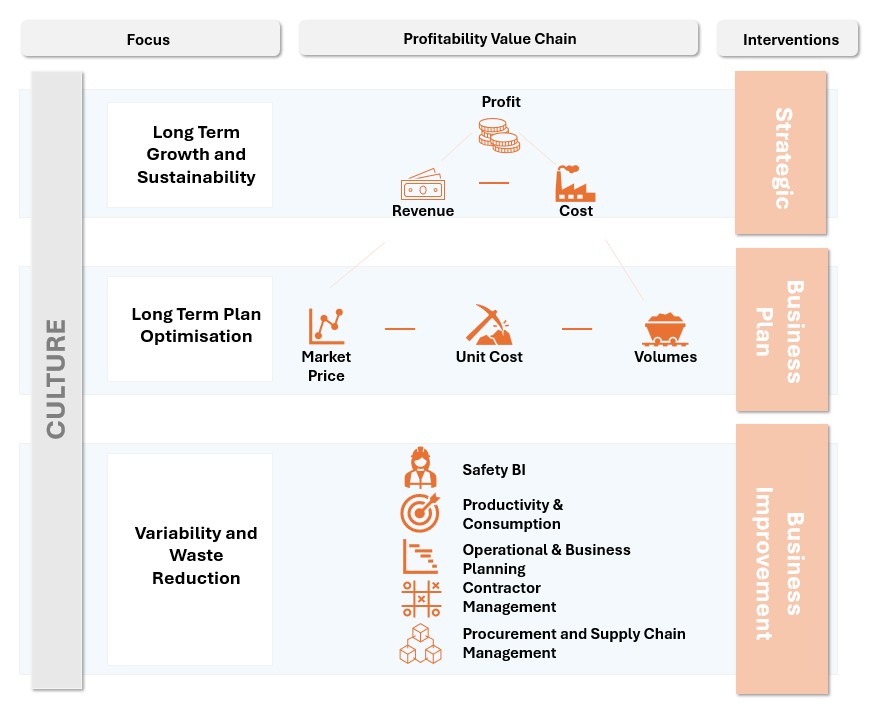

Every organization navigates the ebbs and flows of business cycles, where the dual imperatives of profit and sustainability are constantly tested. Three pervasive pain-points threaten to disrupt this delicate balance: stagnating long-term growth and new ventures, suboptimal business plans, and debilitating variability and process waste. To mitigate these risks, organizations must leverage the profitability value chain, a nuanced framework that reveals the critical levers to pull in times of turmoil. By applying targeted interventions - strategic, business plan, and business improvement - leaders can adeptly address each pain-point, revitalizing growth, optimizing plans, and streamlining operations to restore profitability and sustainability. Will you master the profitability value chain and emerge stronger from the business cycle, or will pain-points hold you back from realizing your full potential?

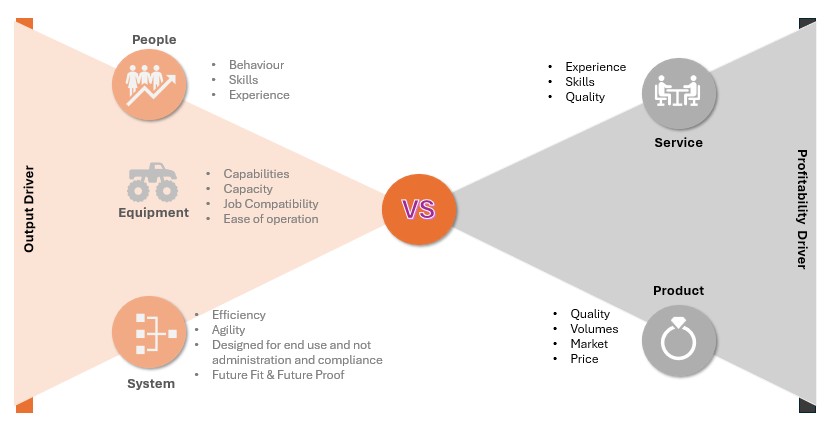

To crack the code on profitability, organizations must first decipher the intricate dance between operational assets, people, equipment, and systems/technology. The sweet spot lies in striking the perfect balance between these elements, as an optimal ratio is the linchpin to unlocking efficiency and productivity. By scrutinizing this delicate balance, leaders can pinpoint the weakest link - whether it's underutilized equipment, inefficient processes, or suboptimal technology - and target interventions to revitalize performance. With this clarity, organizations can break free from the cycle of inefficiency and unlock the full potential of their operational assets, paving the way for sustainable profitability and growth.